Description

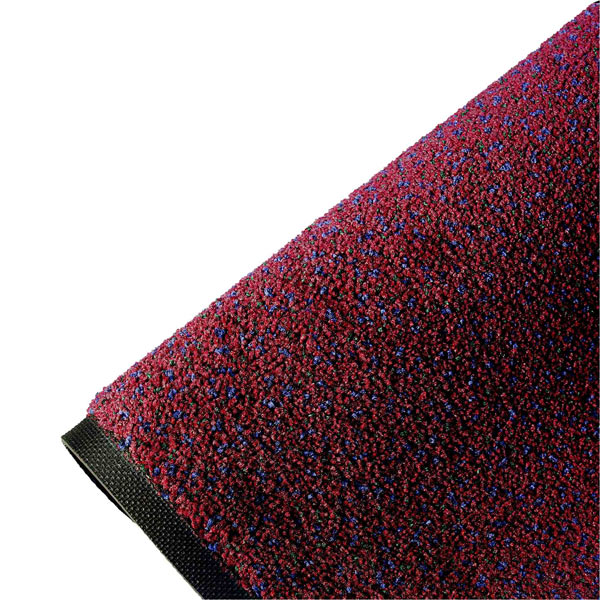

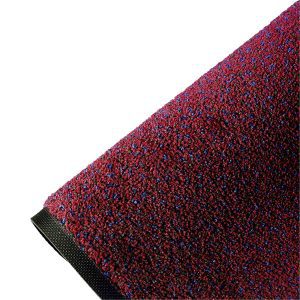

ColorStar Door Mat Product Features:

- 10 year color-loss guarantee with Indoor use. Mats won’t fade due to cleaning.

- Extra course solution-dyed nylon fibers in combination with traditional solution-dyed fibers create excellent scraping and wiping action for maximum soil stopping power.

- Twisted heat-set 100% static-dissipative nylon resists crushing, traps dirt better and extends performance life.

- Green friendly rubber backing has 20% recycled rubber content and is available in smooth or cleated backing types.

- Also available with oil and grease resistant 100% nitrile rubber backing when applications call for additional protection.

- Certified slip-resistant by the National Floor Safety Institute.

- ColorStar door mat Corners can be cut straight or curved.

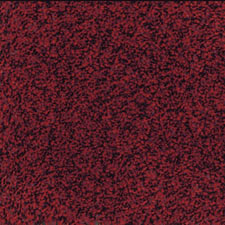

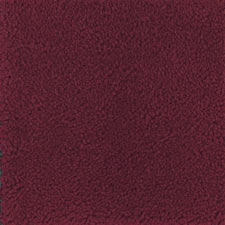

Colors

5′ and 6′ width custom sizes have limited colors available.

Specs

|

GENERAL SPECIFICATIONS:

|

| SURFACE |

|

| FIBER TYPE: |

Solution-dyed BCF 2 ply continuous filament nylon, type 6.0,5^½ twist output, heat set. |

| PILE HEIGHT: |

3/8″ |

| WEIGHT: |

20 oz. per square yard |

| GAUGE: |

5/32″ |

| CONSTRUCTION: |

Cut Pile |

| BACKING TYPE: |

100% SBR Nitrile Rubber (20% Recycled Content) or 100% Nitrile Rubber |

| THICKNESS: |

.060″- SBR Rubber; .050″ – Nitrile Body or .090″ – Nitrile Body |

| TENSIL: |

SBR Rubber = 1400 PSI; Nitrile Rubber = 1800 PSI |

| DUROMETER: |

65 |

| TEMP RANGE: |

Minus 15 degrees F to 130 degrees F |

| TESTING |

ASTM C 1028-29 Static Coefficient of Friction. Dry 70 |

| |

Passes Flammability Standard DOC-FF-1-70 |

| |

Anti-Static maximum average voltage of 1.6 KV as measured by the AATCC 134 Electrostatic Propensity Test and meets IBM’s minimum standard for electrical resistance (NFPA99). |

CLEANING INSTRUCTIONS

1. Vacuum Daily

When possible, Waterhog mats should be vacuumed on a daily basis. During periods of inclement weather, use of a wet/dry vacuum may provide a more effective method of daily maintenance.

2. Routine Maintenance

Spots and non-permanent stains should be removed as needed using a safe non-organic solvent based cleaner. In the event a solvent based spotter is needed, caution should be taken to rinse the excess solvent thoroughly before returning the mat to service. Failure to rinse the solvent can result in damage to the rubber backing of the mat. Periodically, as needed, Waterhog mats should be cleaned using a more vigorous method such as a pressure washer or water hose. Following the use of this method, the mats should be placed in a position to allow them to drain. This draining will occur rapidly and the mats will be ready to put back into service in a short time.

3. Deep Cleaning

Waterhog mats may be cleaned by any routine method used for carpeted floors. This includes wet extraction as well as low moisture extraction methods. Chemicals used for cleaning should be as solvent-free as possible and following a wet cleaning, care should be taken to rinse the mat as thoroughly as possible. If a wet system is used, the mats should be placed in a position to drain as much as possible before returning to service.

4. Floor Preparation

Prior to the mat being put back into service, Logo Mats recommends that the floor where the mat will be placed be cleaned to remove dust and dirt. This will allow the mat to grip the floor more effectively reducing mat movement with traffic.

Reviews

There are no reviews yet.